TheFarmersDigest

The Farmers Digest

May 20, 2025

Editor

Chris Pigge

Editor

Miles Falk

Fencing Systems for Rotational Grazing: Key Components for Success

Let's face it—without good fencing, rotational grazing becomes an exercise in frustration, like trying to herd butterflies with a tennis racket. The right fencing system doesn't just contain animals; it creates an effective relationship between soil, grass, and livestock that can transform worn-out pastures into vibrant, productive landscapes.

Modern agriculture has forgotten something our great-grandparents understood well—animals need to move. Nature never designed herbivores to stay in one place indefinitely. Those massive bison herds didn't remain on the same prairie patch for months; they moved, grazed intensively, and moved again. Their hooves, manure, and grazing patterns worked in harmony with the grasslands in a natural cycle that developed over millennia.

Today's graziers aren't just building fences—they're recreating these natural patterns using modern materials. And the good news? You don't need deep pockets or an engineering degree to get started.

The Fencing Philosophy: Function Before Form

Before putting in your first fence post, understand this basic truth: the perfect fence mostly exists in farm magazines. In the real world, fencing works when it suits your specific animals, your unique land, and—most importantly—your available time and money.

Different animals respond to fences differently. Cattle usually respect even simple electric barriers once trained. Show them the boundary, let them experience the electric shock safely, and they'll generally stay where you want them.

Sheep and goats tend to see fencing more as a suggestion. They usually need either stronger physical barriers or more effective psychological deterrents. As one shepherd said after finding his flock in a neighbor's field: "If water can find a way through, sheep will eventually find the same path."

Your land itself shapes your fencing decisions. The hills, streams, and woods aren't just scenery—they actively affect your grazing system. Working with these natural features rather than against them usually saves money and effort.

Permanent Fencing: Building Long-Term Infrastructure

High-Tensile Systems: Durable and Effective

High-tensile fencing uses strong steel wire under tension to create effective boundaries with fewer posts than traditional fencing.

A properly installed high-tensile fence becomes a lasting farm asset. With proper maintenance, these systems can last 20-30 years, making their initial cost much more reasonable when spread over their lifetime.

The science is simple: wire under proper tension, anchored securely at ends and corners, creates a strong barrier that contains livestock effectively. When electrified, these systems create both physical and mental boundaries that most animals quickly learn to respect.

Installation requires careful attention to detail. Strong corner posts and braces are especially important—they determine whether your fence works for decades or fails during the first storm. Materials might cost $1,000-2,500 per mile for a single-strand system, but the real value comes from installing it correctly so it lasts.

Barbed Wire: Traditional Security

Barbed wire fencing has secured farm boundaries for over a century, and remains a practical option for perimeters and even paddock divisions in many operations. Consisting of twisted wire with sharp barbs spaced at regular intervals, it creates an effective physical deterrent.

For cattle operations especially, barbed wire provides a cost-effective perimeter solution that clearly marks property boundaries while deterring livestock from testing the fence line. A typical five-strand barbed wire fence costs approximately $2,000-4,000 per mile in materials, positioning it between basic high-tensile electric and woven wire options in terms of expense.

While less commonly used for interior paddocks in intensive rotational systems, some operations successfully use three or four-strand barbed wire divisions for larger paddocks or less frequently rotated areas. The primary drawbacks include higher injury risk compared to smooth wire alternatives and the inability to easily move or modify the fence once installed.

Modern rotational systems often combine barbed wire perimeters with more flexible interior fencing, leveraging the security of traditional methods with the adaptability of newer technologies.

Woven Wire: Physical Security

For farms dealing with escape-prone animals, predator concerns, or different livestock types, woven wire fencing offers substantial physical security. With its connected horizontal and vertical wires, it creates a strong barrier whether electrified or not.

This reliability comes with clear trade-offs. More materials, closer post spacing (typically every 8-12 feet), and more difficult installation raise costs to $8,000-12,000 per mile. This big difference leads many farmers to carefully consider where such security is truly needed.

Smart operators use woven wire strategically—for property boundaries or areas with specific security concerns, while using cheaper options for interior divisions. This balanced approach puts resources where they matter most while controlling overall costs.

Temporary Systems: Flexibility and Adaptation

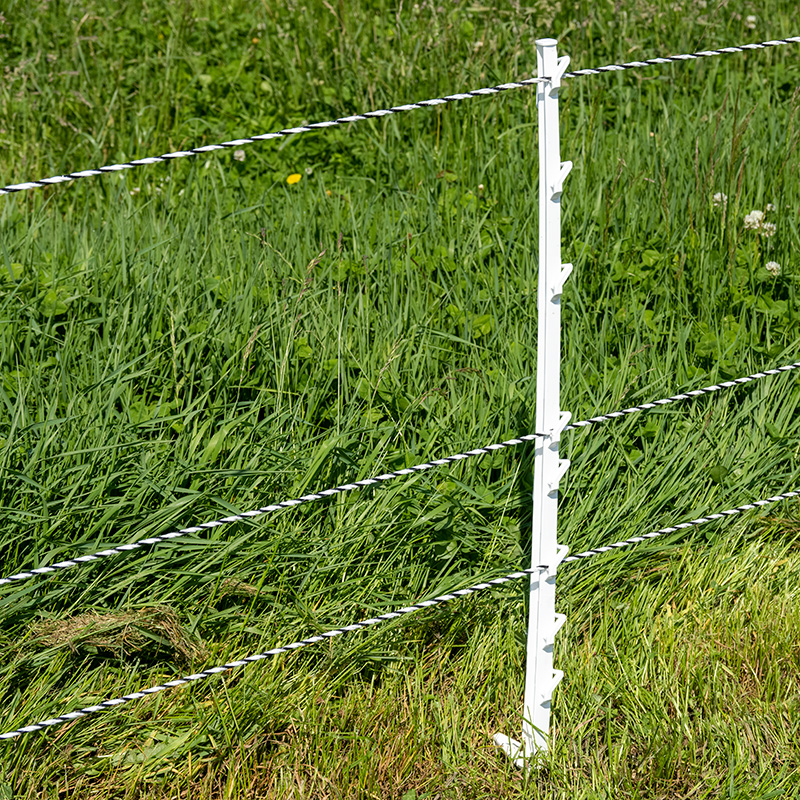

Polywire and Polytape: Practical Portability

While permanent fencing provides stability, portable electric systems like polywire offer exceptional flexibility. These synthetic cords with embedded metal wires have made frequent livestock moves practical and affordable for farms of all sizes.

Their effectiveness comes from simplicity and ease of use. Lightweight and easily moved, polywire works with step-in posts to create paddock divisions that one person can set up or change in a short time. Despite their minimal appearance, when properly electrified, these systems effectively control most livestock.

For those just starting rotational grazing, these systems provide an accessible entry point with reasonable investment. Basic polywire costs about $0.10-0.15 per foot, allowing you to experiment with different paddock layouts before committing to permanent infrastructure.

Polytape, with its greater width, improves visibility for both animals and humans. This better visibility justifies its slightly higher cost ($0.20-0.40 per foot) by reducing accidental contacts and improving overall system effectiveness, particularly with horses or where visitors might be present.

Training Animals to Respect Electric Fencing

The effectiveness of any electric fence system depends largely on proper livestock training. Here's a straightforward approach to teaching animals to respect even a single strand of electric fencing:

- 1. Create a small training area using a highly visible electric fence (polytape works well for this) with multiple strands initially.

- 2. Ensure your energizer delivers adequate voltage—at least 4,000–5,000 volts for cattle and 6,000+ for sheep or goats.

- 3. Introduce animals to this area when they're calm, not hungry or thirsty, allowing them to discover the fence naturally.

- 4. When an animal receives its first shock, give it space to react and learn. Most will back away and become cautious around the fence.

- 5. Keep animals in this training area for 2–3 days, allowing the entire herd or flock to learn about the boundary.

- 6. Once animals show respect for the fence (standing back from it, showing caution), you can transition to simpler single-strand systems for daily rotation.

- 7. Maintain consistent voltage—animals quickly learn when a fence is no longer working and will test it if they detect weakness.

- 8. Periodically check that vegetation or fallen branches aren't shorting out the fence, which can teach animals to ignore the boundary.

This training process creates a psychological barrier that becomes more important than the physical fence itself. Well-trained livestock will respect even minimal physical barriers if they associate them with electric shock.

Electric Netting: Comprehensive Containment

For smaller livestock or situations with predator pressure, electric netting combines physical barriers with psychological deterrence in pre-made fence sections. These systems work particularly well with sheep, goats, poultry, and other animals that often challenge regular fencing.

The standard configuration includes 164-foot rolls with built-in posts every 8-12 feet. Priced at $1.50-2.25 per foot, electric netting costs more than basic polywire but provides much greater security. For operations where animal losses or predation cause significant economic risks, this additional cost often proves worthwhile.

Hybrid Systems: Practical Combinations

Experienced graziers often recognize that combining permanent and temporary elements creates optimal systems. These hybrid approaches leverage the strengths of different fencing types to balance security, flexibility, and cost-effectiveness.

A common approach uses permanent high-tensile or barbed wire perimeter fencing for secure property boundaries, with temporary interior divisions that can adapt to seasonal conditions, forage availability, or management goals. This structure provides overall security while maintaining internal flexibility.

Another effective strategy establishes permanent lanes connecting water sources, handling facilities, and other fixed infrastructure, with temporary fencing subdividing larger areas into appropriate grazing cells. This design ensures consistent access to essential resources regardless of rotation pattern.

The practical value of hybrid systems comes from their efficiency—using the right tools for specific purposes rather than applying a uniform approach across all situations. This practical perspective focuses on functional results rather than theoretical ideals.

Fencing Systems by the Numbers

- $1,000-2,500Typical per-mile cost range for single-strand high-tensile electric fence materials (University of Missouri Extension, 2023)

- $4,875-15,005Approximate per-mile cost for five-strand barbed wire fence materials and installation (Oklahoma State University, 2022).

- $4,000-8,000Approximate per-mile cost for five-strand high-tensile electric fence materials and professional installation (USDA NRCS, 2022)

- $1,600-2,400Typical per-mile cost for woven wire field fence installation (Penn State Extension).

- $0.10-0.15Per-foot cost of basic polywire (Pennsylvania State University Extension, 2024)

- $0.20-0.40Per-foot cost of heavy-duty polytape (Pennsylvania State University Extension, 2024)

- $1.50-2.25Per-foot cost of portable electric netting (University of Kentucky, 2023)

- 3-5 hoursAverage labor time to set up 1/4 mile of portable polywire fencing with step-in posts (Michigan State University Extension, 2024).

- 20-30 yearsExpected lifespan of properly installed high-tensile fencing (Cornell University, 2022)

- 5-8 yearsAverage useful life of portable electric fencing with regular use (Ohio State University Extension, 2023)

Water Systems: Essential Complementary Infrastructure

No rotational grazing system works effectively without adequate water access. Even the best-designed paddock arrangement fails if animals can't drink properly. As one experienced rancher stated: "Without accessible water, even excellent fencing becomes useless."

Permanent water systems—typically using buried pipelines with frost-proof hydrants—provide reliable year-round access regardless of weather. While these systems require substantial initial investment, they significantly reduce daily labor and improve overall management efficiency.

Portable water options, including movable tanks and temporary pipeline extensions, offer flexibility with increased labor demands. Many operations begin with this approach, developing more permanent infrastructure as their grazing system evolves and resources allow.

The hybrid water strategy works like hybrid fencing—creating permanent access points at strategic locations while using portable components to extend distribution as needed. A common implementation positions a central permanent water source with paddocks designed to keep walking distances reasonable, typically quarter-mile or less.

Trade-Offs and Considerations

Investment vs. Flexibility

Permanent fencing generally involves higher initial costs but reduces ongoing labor. A comprehensive high-tensile perimeter system might require $4,000-8,000 per mile initially, but can function effectively for decades with minimal maintenance.

Temporary systems need less capital investment but demand more regular attention. Basic polywire fencing materials cost substantially less per foot, but typically require replacement every 5-8 years with regular use and need more frequent adjustments and monitoring.

Labor Requirements

Installation effort varies significantly between systems. Permanent high-tensile fencing requires careful installation with proper tensioning and bracing, often taking 30-40 hours of labor per mile. Temporary systems can be deployed much more quickly but need regular movement and maintenance as part of the rotation schedule.

The labor equation extends beyond installation to daily operation. Moving livestock through well-designed permanent infrastructure might require minimal time, while reconfiguring portable fencing for each rotation represents a more substantial time commitment.

Land Use Flexibility and Whole-Farm Integration

Perhaps the most overlooked advantage of temporary fencing systems is the land use flexibility they provide. When paddocks are divided using portable fencing, those same areas can be:

- Cut for hay during peak growth periods

- Planted to annual crops when rotation schedules indicate

- Mechanically managed for weed control or pasture improvement

- Temporarily removed from the grazing rotation without wasted infrastructure

Permanent interior fencing, while labor-saving for grazing, effectively locks those paddocks into a single use pattern. The posts, braces, and wires that make permanent fencing effective also create obstacles for haying equipment, tillage implements, or other mechanical operations.

Adaptability and Evolution

Temporary systems allow operations to refine their approach through direct experience, adjusting paddock configurations based on observed results. This flexibility proves particularly valuable during the early stages when determining optimal rotation patterns for specific conditions.

Permanent infrastructure offers consistency and reliability but less opportunity for adjustment without additional investment. Many successful operations recommend starting primarily with temporary systems, gradually installing permanent components once effective patterns become established through practical experience.

Thinking Holistically: The Whole-Farm Perspective

When planning fencing systems for rotational grazing, taking a holistic view of the entire operation often reveals opportunities and constraints that might otherwise be overlooked. Consider these broader perspectives:

- 1. Future land use plans: How might your land use change over the next 5–10 years? Will certain areas potentially transition to crops, silvopasture, or other uses? Keep these areas flexible with temporary fencing.

- 2. Multi-species potential: Even if you currently raise only cattle, might sheep, goats, or poultry enter your system in the future? Design with the most demanding species in mind.

- 3. Seasonal dynamics: How do water sources, shade availability, and forage growth patterns change throughout the year? Your fencing system should accommodate these seasonal shifts.

- 4. Equipment and machinery: Will haymaking, seeding, or mechanical weed control be needed in your grazing areas? Ensure your fencing approach doesn't create unnecessary obstacles.

- 5. Labor availability: Be realistic about available labor for daily moves and maintenance. The ideal system on paper becomes worthless if it demands more time than you can consistently provide.

Only after considering these broader factors should you refine your approach to specific fence types, materials, and layouts.

Real-World Applications

SARE Research Farm Implementation

A SARE-funded project (ONE10-113) documented a northeast dairy farm's transition to management intensive grazing using a combination of high-tensile perimeter fencing with portable interior divisions. The project demonstrated how farms could implement rotational grazing with reasonable infrastructure investments while maintaining flexible land use.

SARE Project Report ONE10-113 (Benson, 2011)

NRCS Technical Implementation

The USDA Natural Resources Conservation Service documented multiple farms implementing rotational grazing systems under their Conservation Practice Standard 512. These implementations demonstrated how proper fencing placement can complement other conservation practices while improving forage utilization.

USDA NRCS Conservation Practice Standard (2022)

Kentucky Research Implementation

University of Kentucky research on small ruminant fencing options documented the effectiveness of electric netting systems for sheep and goat operations. Their published findings (ID269) provide comprehensive guidance on design considerations and cost factors for various fencing configurations specifically suitable for small ruminants.

University of Kentucky Publication ID269 (2023)

Getting Started: Implementation Strategy

For those new to rotational grazing, beginning with temporary infrastructure often proves most practical. Consider this progressive implementation approach:

- 1. Start with a simple division of existing pasture using the most appropriate temporary fencing for your livestock class.

- 2. Observe animal behavior, forage response, and management patterns throughout at least one complete growing season.

- 3. Gradually increase paddock numbers as management comfort grows, continuing to use primarily portable infrastructure.

- 4. When consistent patterns emerge, consider strategic permanent investments—perhaps corridors connecting water sources or fencing for paddocks that maintain consistent dimensions.

- 5. Continue developing the system based on observed results, balancing infrastructure investments with management objectives and practical constraints.

Remember that even basic rotational systems typically outperform continuous grazing, making "good enough" implementation far better than perpetual planning without action.

Conclusion

Effective fencing systems for rotational grazing balance infrastructure investment with operational flexibility, adapting to landscape characteristics and management goals. While the range of options may initially seem complex, most successful operations begin simply and evolve through practical experience.

By approaching fencing decisions with clear priorities—whether minimizing costs, reducing labor, or maximizing adaptability—producers can develop infrastructure systems that enhance rather than complicate their grazing management. The fencing system serves primarily as a tool enabling the real objective: improved pasture-livestock relationships that benefit overall agricultural productivity.

Whether implementing high-tensile permanent fencing, portable temporary systems, or strategic combinations, the most important step remains initiating the process. Providing pastures with appropriate recovery periods generally yields positive results regardless of the specific fencing technology used to create those recovery opportunities.

References

Benson, A. F. (2011). Management Intensive Grazing for Dairy Heifers. SARE Project Report ONE10-113.

Michigan State University Extension. (2013). Bale Grazing Popularity Continues to Grow.

Ohio State University Extension. (2021). Rotational Grazing and Water Quality.

Oklahoma State University. (2022). Oklahoma Farm and Ranch Custom Rates, 2021-2022.

Pennsylvania State University Extension. (n.d.). Woven Wire Fencing.

University of Kentucky. (2023). Small Ruminant Fencing Options.

Regenerative Farmers of America. Farming Tips. Fencing Options for Rotational Grazing.